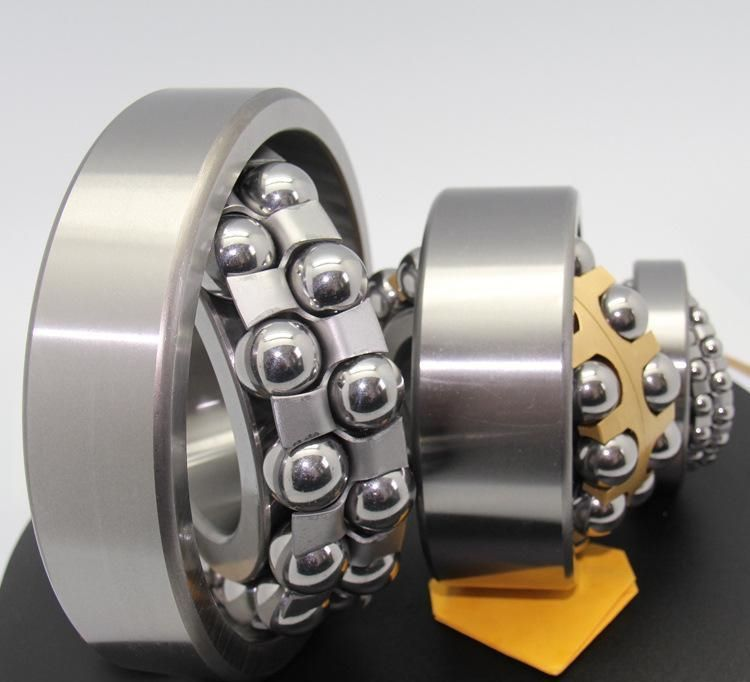

Introduction to knowledge of bearing friction and temperature rise

Bearing temperature rise: The friction of rolling INA bearings is a key factor in determining bearing heating and operating temperature. The friction loss of the rolling bearing is almost all converted into heat inside the bearing, which causes the temperature of the bearing to rise. Generally, the temperature rises sharply at the beginning of operation, but it is basically stable when it reaches a normal state. The time to reach a steady state varies with the heat generated by the bearing, the heat capacity of the bearing housing, cooling area, amount of lubricating oil, and ambient temperature. The reasons for the abnormal temperature rise are: too small clearance, too large pre-pressure, too much or insufficient lubricant, mixing of foreign matter and heating of the sealing device, etc.

Regarding the heat treatment swelling technology of bearing rings, the troublesome thing is the large amount of swelling, especially when the bearing ring product has a large swell after heat treatment, the lighter is to increase the grinding allowance and the number of grinding times of the bearing ring. It will directly cause the bearing ring to be scrapped. What are the factors that cause the bearing ring to expand a lot after heat treatment? How to solve this problem? Share relevant knowledge below:

The factors that cause bearing ring swelling after heat treatment are well known. The quenching swelling of bearing ring is caused by the specific tolerance of the structure of pearlite before quenching and martensite after quenching. In addition to the structural transformation of the steel heat treatment, thermal stress and structural stress are also generated. If the instantaneous stress exceeds the yield strength of the structure, it will cause plastic deformation to change the actual expansion. In addition, the presence of retained austenite and the appearance of non-martensite also affect the amount of swelling. The content of various components in the structure formed after quenching and the size of the residual stress are the main factors that determine the change of the quenched and tempered size of the bearing steel.

Solution to a large amount of swelling of bearing rings after heat treatment

(1) Adding Kerun additives to the hot oil can reduce the swelling of the quenched product of the bearing ring and increase the qualification rate of the swelling. (2) Improving the cooling cycle of the quenching oil can reduce the amount of expansion of the bearing ring after quenching. (3) The swelling amount of the bearing ring after quenching has a larger relationship with the structural size of the bearing ring. Some bearing ring swells and some bearing ring shrinks. (4) The swelling amount of the bearing ring products that are quenched by cold oil is relatively small.